BILLIONS OF PRODUCTS LEAK TESTED

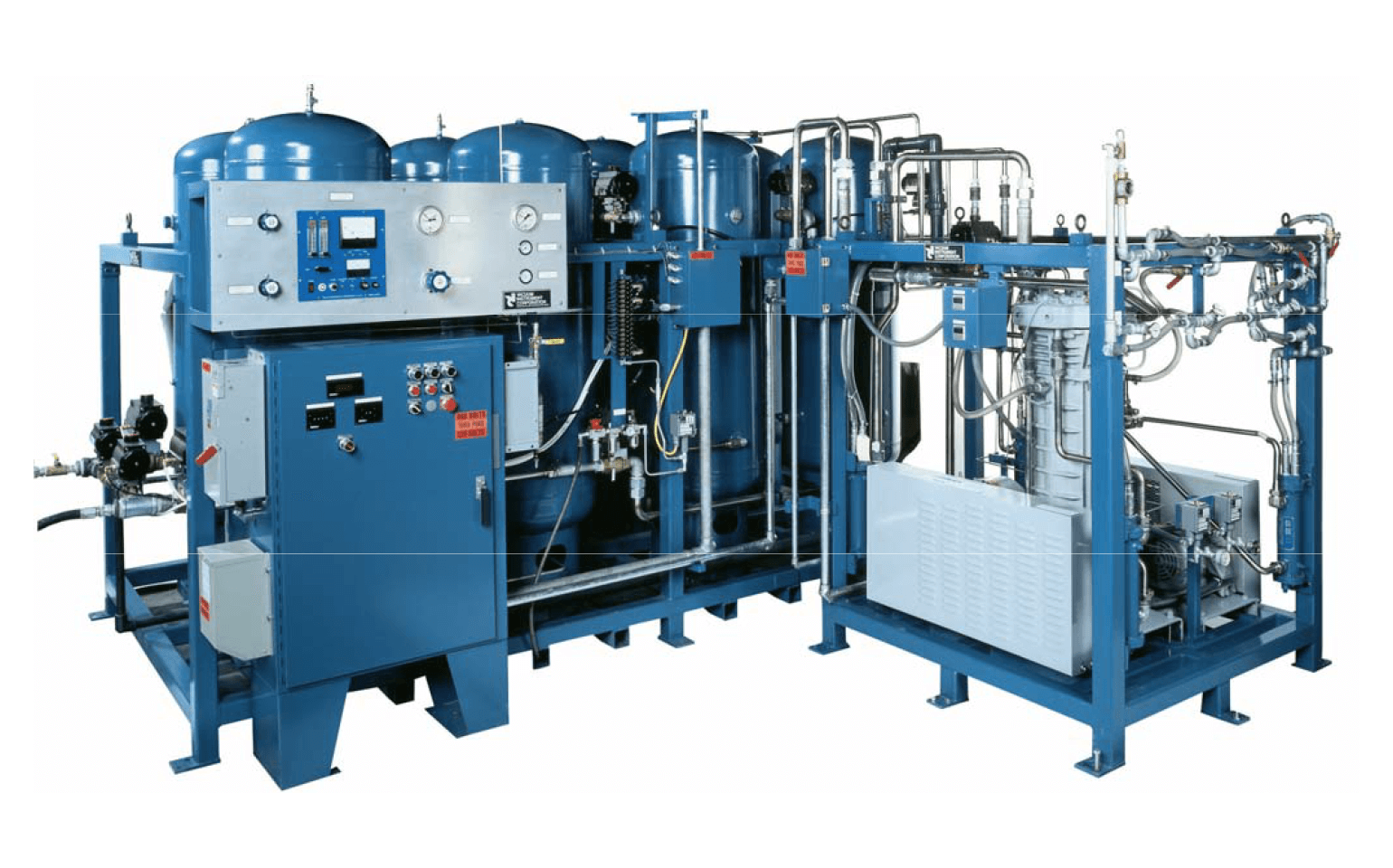

Unlock unparalleled efficiency and innovation in your industrial operations with our expertly engineered Custom Systems. At Direct Solutions, we specialize in designing and integrating tailor-made systems that meet the unique needs of industry leaders. Our commitment to precision and quality ensures that every custom solution enhances performance, optimizes productivity, and drives success in the most demanding industrial environments. Partner with us for custom systems that set new standards in industrial excellence.

STANDARD PRODUCTS

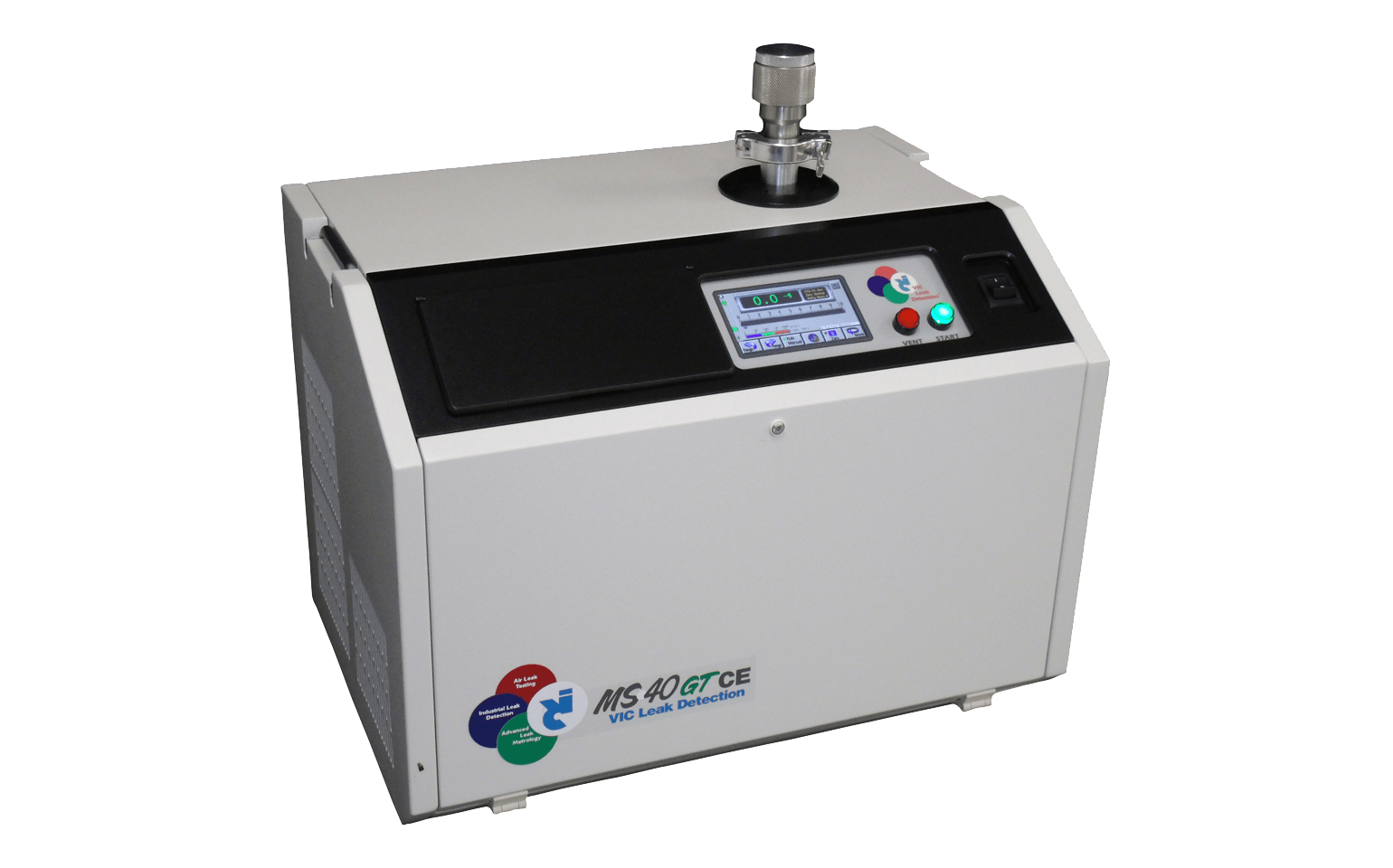

TRACER GAS LEAK TESTERS

Vacuum Instruments Corporation is one of the world’s largest companies devoted solely to the research, design, manufacture, distribution, and service of leak detectors and complete leak detection solutions. VIC is the only company in North America to offer both organically manufactured instruments and custom systems for tracer gas and air leak tests as well as gas management.

GAS HANDLING SYSTEMS

THE RIGHT TOOLS FOR YOUR INDUSTRY

With over 60 years of unsurpassed technology capabilities and unparalleled engineering, we have assisted product, device, and component manufacturers with unique applications in the medical, automotive, aerospace, air conditioning, appliance, chemical, electronics, food & beverage packaging, HVAC, medical, military, opto-electronics, packaging, pharmaceutical, refrigeration, research & development, science & technology, semiconductor, utilities, and vacuum technologies industries with a custom fit solution. Send us your application requirements, leak detection rate requirements, project engineering specifications, and product/device/component being tested, so we can design a leak detection and integrated systems solution that’s right for you.

INTERNATIONAL SUPPORT DEDICATED TO & CLOSE TO OUR CUSTOMERS

Total customer service and application support are as important to manufacturing operations as product performance and reliability.

Vacuum Instruments Corporation, with the world’s largest base of installed leak detectors, provides total customer support.

Service Contracts | Upgrade Packages | Product & Application Training | Remote Technical Support & On-site Labor Support | Depot-level Maintenance and Repair | Spare Parts | Rentals | Gas Leak Recalibration

Cooper Standard is a leading global supplier of systems and components for the automotive industry. Mr. Carrasco stated that Cooper Standard Automotive chose to do business with VIC because they are “a very professional company and are experts in the field of leak detection”. Cooper Standard makes every effort to ensure that the components and materials used in their products maintain high-quality standards. That is why they chose VIC. “Using VIC for leak testing our products gives me the confidence I need to ensure we are passing along quality parts to our customers.”

Ruben Curiel has been in the leak detection business for over 25 years and using VIC equipment for over 20 of those years. “My oldest VIC machine is from 1996 and is still running”, said Ruben Curiel. Ruben reports they solved all their leak detection problems by switching to Vacuum Instruments Corporation. “The construction of the VIC chambers is much more robust and the quality of the welds is much better. We have been running the same machine for over 20 years with no leaks.” When asked why he has been working with VIC, Ruben shared, “I just like them. I can call at all hours. They just help me. Their support is highly recommended.

TEMO is engaged in custom design and manufacturing of cooled Infrared sensor assemblies for DOD tactical and Space applications. TEMO has been in business for 40 years, participating in the US Air Force program and eight different space programs since 2003. Ram states, “I’m good because VIC is good.

MANUFACTURING, DESIGN AND R&D IN THE USA

At Vacuum Instrument Corp., we take pride in our unwavering commitment to manufacturing, designing, and conducting research & development right here in the United States. Our dedication to innovation and quality is powered by the expertise of American engineers and skilled workers, enabling us to develop not only cutting-edge solutions but also custom systems tailored to meet the specific needs of industries worldwide. Embracing a “Made in the USA” ethos, we not only contribute to the domestic economy and job creation but also ensure that our customers receive products that meet the highest standards of precision, reliability, and customization.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.