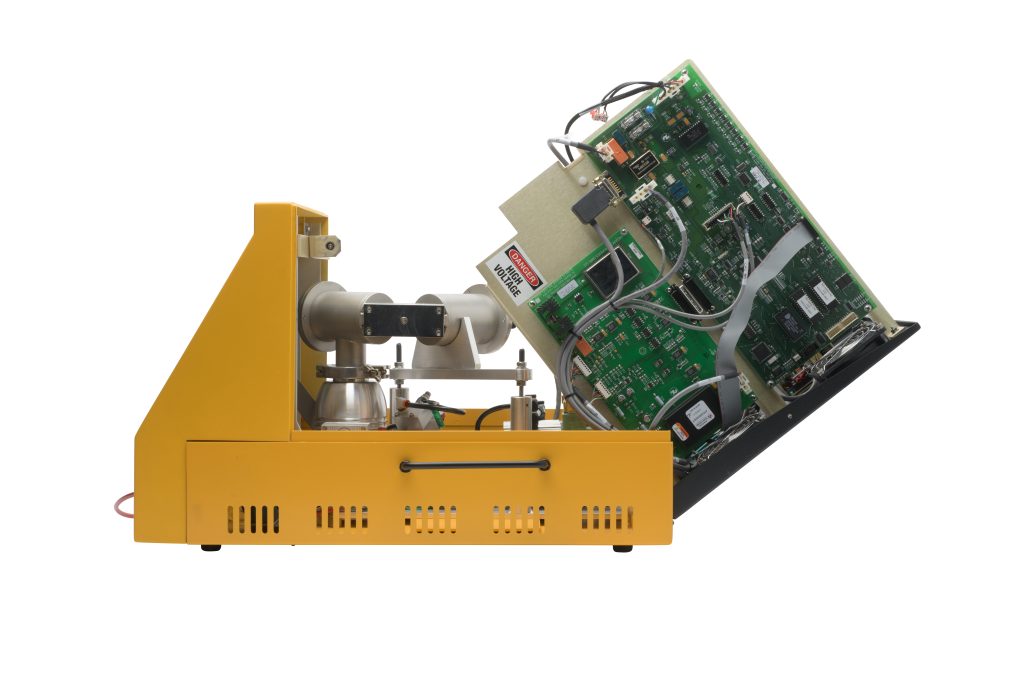

MD-490S

HELIUM LEAK DETECTOR

PORTABLE DRY HELIUM LEAK DETECTOR SNIFFER MODEL

The MD-490S is a leader among portable tracer gas leak detectors. With a response time of less than 0.5 seconds, sensitivity to 10-8 direct reading atm-cc/sec, and the ability to zero out the background, this is the industry’s most aggressive portable leak detector.

The MD-490S is fully integratable with our SmartCharge 5 and Evacuation and Backfill Station.

It also meets the stringent requirements for robustness, reliability and ease of maintenance that are essential in any industrial environment..

MD-490S: APPLICATIONS

Main Features

- Fastest response time in the industry (less than 0.5 seconds)

- Helium background suppression

- Maintenance free, dry pump

- Sensitivity to 5 x 10-8 atm cc/sec

- Less than 3 minutes total start-up time

- Fully automatic calibration sequence with built-in 10-5 atm cc/sec gas leak

- Front panel key lock-out

- Sealed membrane keypad

- Fully interactive system diagnostics with multilingual displays

- High output (110dB) adjustable audio alarm

Flexible Communication Format

- Option Full Duplex RS232 communication

- Option AC & DC PLC Interfacing

- Option Analog Outputs

- Option Data Link Software

| MEASUREMENT CHARACTERISTICS |

|---|

| Sensitivity using Helium | 5 x 10-8 atm cc/secs |

|---|---|

| Response Time | < 0.5 sec |

| Measuring Scale | 7 decades |

| TEST MODES |

|---|

| Flow Units | cc/sec, oz/yr, Pa m3/s |

|---|---|

| Gas | Helium Sniffing Test |

Options

- VIC exclusive Vibrated-Probe w/built-in Auto Zero switch

- Carrying Case

- Portable Cart

Accessories

- Smart Charge 5, Gas Handling Unit

- Test Booths and Fixturing

- Multi-point probes

- Robotic Sniffing

- Leak calibrator

- Master leak

- Connectors…

| TECHNICAL SPECIFICATIONS |

|---|

| Weight | 31.8 kg / 70 lbs |

|---|---|

| Dimensions (WxHxD) | 344×395 x618 mm / 13.5″x15.5″x24.4″ inch |

| Electrical Supply |

115/220 VAC, 60/50 Hz 6/3 Amps; CE Compliant |

| Temperature |

Operating: +00C to +460C Storage: 00C to +600C |

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.