MILITARY & DEFENSE APPLICATIONS

Military and Defense equipment leak testing is essential to ensure the reliability and safety of mission-critical military hardware. Utilizing advanced leak detection systems, such as helium leak testing and functional leak testing, we provide comprehensive solutions tailored for military applications. Our leak test solutions are designed to meet the rigorous demands of military standards, ensuring the integrity of components like optical sighting devices, fire suppression canisters, and ammunition.

Ensuring Safety with a Leak Testing System

Military, Aerospace and Defense are all associated with mission critical products. That is why Defense contractors employs some of the strictest testing regulations of any sector. Leak detection testing is one of the techniques used to confirm the integrity of essential parts and components during assembly.

Our cutting-edge leak detection systems, including tracer gas and custom leak testing systems provide comprehensive solutions tailored to the unique requirements of military applications. These systems are designed to detect even the smallest leaks, preventing failures in the field.

Whether you use air, helium, hydrogen, or argon, we offer a wide range of systems to meet your specific requirements.

MANHATTAN PROJECT

The founders of VIC were part of the development of the first leak testers ever made as part of the Manhattan Project. As the only Helium Leak Test supplier that qualifies for Made in America, our dedication to the military industry continues today. VIC products meet MIL-STD-1441, MIL-STD-883k methods and other.

The Manhattan Project, a covert World War II initiative led by the U.S., aimed to develop atomic weapons, marking a significant leap in scientific and military capability. Spearheaded by figures like Robert Oppenheimer, it pooled immense resources and talent, culminating in the creation of nuclear technology. While it dramatically shifted the course of warfare and international relations, it also sparked ongoing debates about the ethics and implications of nuclear power.

EXAMPLES OF COMPONENTS TESTED

For decades, VIC has been leading the way in testing solutions for military and defense equipment. Our expertise and commitment to innovation make us the preferred choice for defense manufacturers worldwide. We continually invest in research and development to bring the latest advancements in test equipment and methodologies to our clients, ensuring the highest standards of safety and reliability in mission-critical applications.

Optical Devices

Ammunitions

Nose Cones

Gas Mask

Fire Suppression Canister

Pressure Vessels

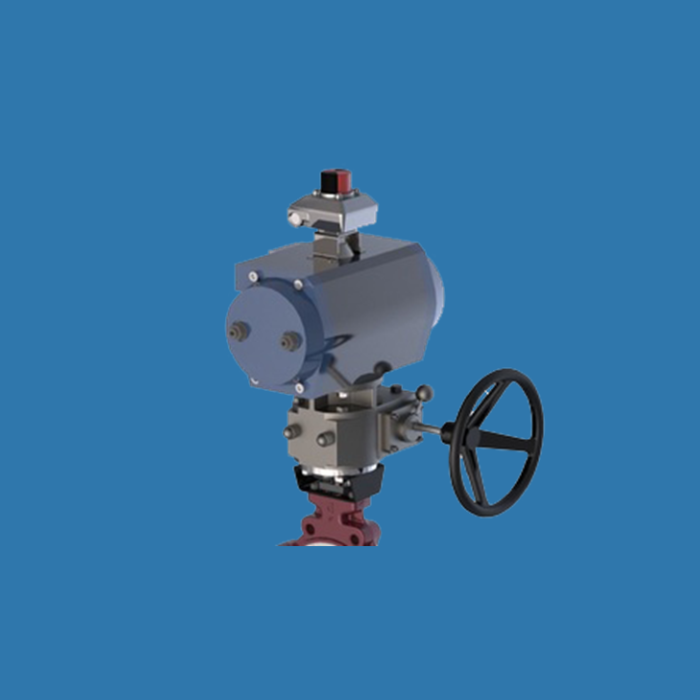

Pneumatic Actuators

Missile Housings

Hydraulic System

Ammunition Case

Communication Devices Enclosure

And More…

EXAMPLES OF CUSTOM LEAK TEST SYSTEMS

In the military and defense industry, components such as fuel tanks, hydraulic systems, and missile housings require rigorous leak testing. VIC offers custom leak test systems designed to meet the unique needs of these critical components, ensuring the highest standards of safety and reliability.

STANDARD TRACER GAS LEAK TESTERS

For defense and military manufacturers seeking reliable and efficient test solutions, VIC offers a comprehensive suite of equipment designed to meet the industry’s highest standards. As a leader in the leak testing industry, our innovative solutions ensure the quality and performance of automotive components, enhancing safety and reliability for end consumers.

ARGON LEAK TESTER

Some leak test applications cannot utilize Helium as a tracer gas, but users will want the benefits of leak testing with an inert gas. Argon has proven to be a very effective tracer gas, but because 1% of the atmosphere is comprised of Argon there are challenges with using VIC. VIC customers have been using our Argon leak testers for over 20 years because VIC produces the only leak tester designed specifically for leak testing with Argon.

Many components are too large to be tested with a benchtop unit with a Bell Jar or Test Cup. VIC created the Intrepid series of Custom Leak testers to address the needs of Military contractors in leak testing large subassemblies and final assemblies in a leak test system. The Intrepid line of leak test systems can; 1) utilize Helium or Argon, 2) accommodate even the largest of parts and 3) support a variety of leak test methods, including but not limited to; Under Vacuum Leak Detection, Evacuation and Helium Spray, etc.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.