VIC EXCELLENCE IN CUSTOMER SUPPORT

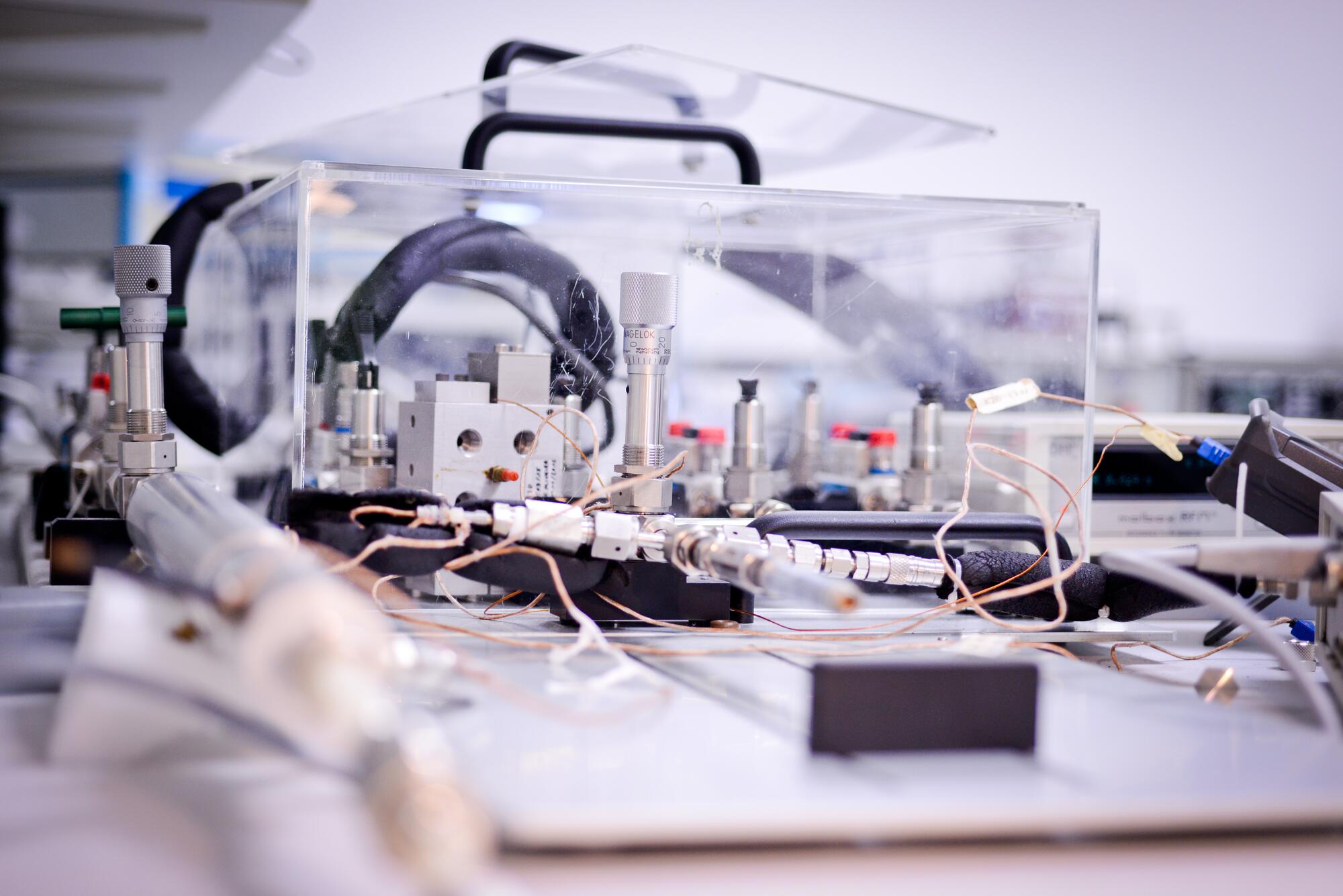

International support – Dedicated to and close to our customers, Total customer service, and application support are as important to manufacturing operations as product performance and reliability. Vacuum Instruments Corporation, with the world’s largest base of installed leak detectors, provides total customer support.

- Single source for sales, service, and support. VIC engineers design both the leak test instrument and the system in which that instrument is used, so a single service call supports every aspect of every installation.

- Unparalleled process application experience and assistance by factory-trained specialists who can help to improve their customers’ manufacturing yields, productivity, and product quality.

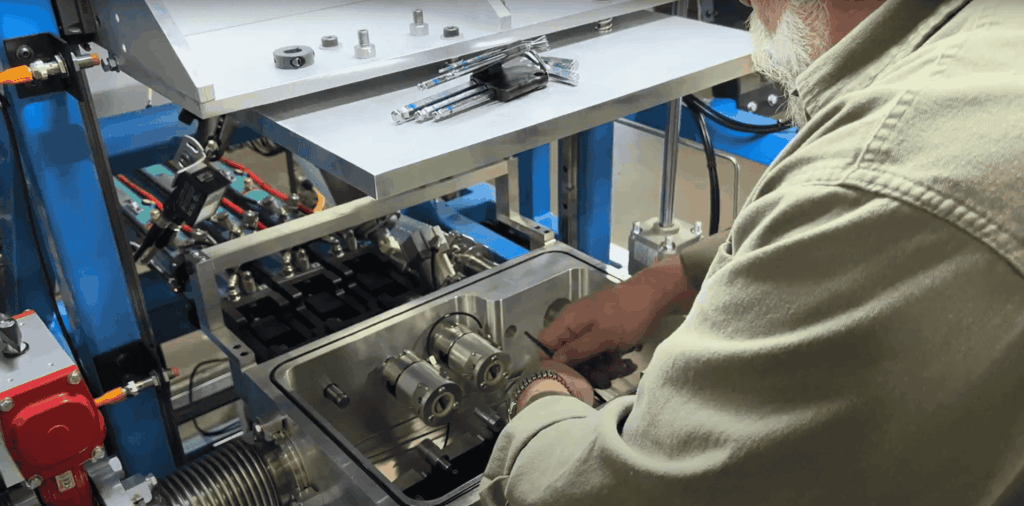

- Every system is designed, built, and tested by our own dedicated staff. Customer training and service by factory-trained specialists are available worldwide.

- Training, custom-tailored to individual needs, either in-house or on-site.

- Maintenance contracts, and service plans customized to individual needs.

- Worldwide telephone support and quick-response service directly from the factory for the leak test instrument, the leak test system, and the application integration.

- One call to one company for sales, process application assistance, training, and service—total customer support.

REMOTE TECHNICAL SUPPORT

Remote Technical Support provides access to a factory-trained VIC engineer via email or telephone for assistance with your questions and troubleshooting. VIC technical engineers are here to help diagnose issues over the telephone so that you can get back to production quickly.

ON-SITE LABOR SUPPORT

On-site Labor Support is field service that is performed by a factory-trained VIC engineer at your facility. The VIC Field Service program provides unparalleled process application expertise directly to your production line. On-site services can include evaluation, repair, or maintenance. VIC’s service centers in the USA, Mexico and Europe permit rapid response—typically within 24 hours of request.

SERVICE AGREEMENTS

Vacuum Instruments Corporation offers customers a service agreement. This custom-tailored service agreement provides solutions for each customer installed base, which requires preserved high yield rates for the parts under test, minimized unscheduled down time costs, and wants to preserve the lifetime of the leak detection assets, whether instruments or custom systems.

Our Service Team works closely with you to review your installed base and explore your service options to recommend a service program to suit your needs. There are several different support options available, which can be selected a la carte as necessary to meet your budgetary and installed base support requirements.

SERVICE OPTIONS

Preventative Maintenance

- Performed on-site Material and Labor

- Kits Only – Customer Labor

- Scheduled to Accommodate Production

- Recalibrate Gas Leaks

Leak Detector Repair/Overhaul

Parts & Repairs Coupons

Material Support Price Freeze

Labor Bank

Technical Support

- Phone Support Free

- Service Levels

- 24-hour on-site response

- 72-hour on-site response

- Response as soon as able

Inventory Management

- Consignment of PM Kits and consumables

- Additional Spares

Installed Base Options

For your convenience, VIC offers service agreements for all of our equipment at your site, a partial selection of your equipment at your site, or for multiple sites.

Term Options

Service contracts are typically renewed on an annual basis, but multi-year contracts can be accommodated and are more cost-effective in some cases.

Extended Warranty Option

The Extended Warranty option is a popular option. This type of agreement may allow a service agreement to be included in the CAPEX cost of purchase as opposed to OPEX costs.

As with all VIC solution-based offerings, flexible billing terms are available to suit your budgetary requirements. Billing can be set up, annually, quarterly, or monthly.

DEPOT-LEVEL MAINTENANCE & REPAIR

The Depot repair program offers comprehensive factory service for our leak detectors, an excellent value for revitalizing equipment.

This program allows customers to return a unit to our corporate Headquarters in NY for evaluation and maintenance. Upon receipt and evaluation of the unit, customers receive a written estimate outlining the repairs or maintenance required to return the unit to factory operating condition. Repairs are conducted only upon customer authorization. Lead time is typically 1 to 2 weeks after authorization.

USER MANUAL REQUEST

Need a copy of your product manual?

Simply fill out the form below to request it, and we’ll send the correct manual straight to your inbox. Whether you’ve misplaced your original copy or just need a digital version, we’re here to help you get the information you need quickly and easily.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.