LEAK DETECTION FOR DATA CENTER COOLING SYSTEMS

COOLING SYSTEMS l DATA CENTER APPLICATION

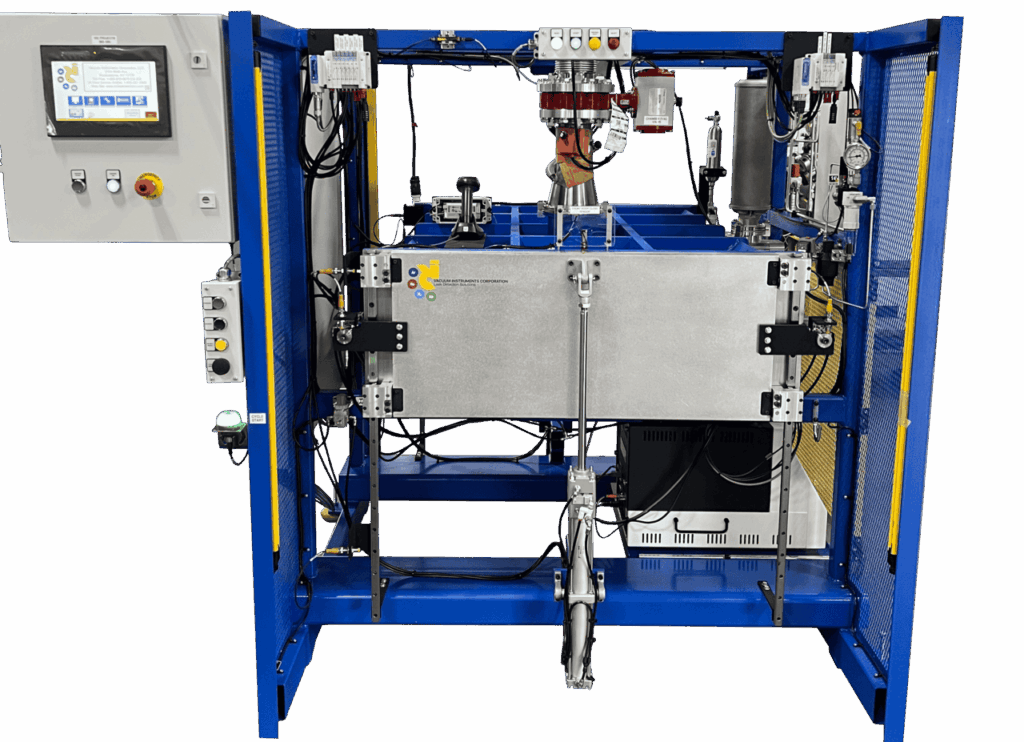

Our advanced Through-Chamber Leak Testing System is designed for seamless integration into factory conveyor systems, providing efficient and automated testing of cooling system components used in large data centers. This high-precision system ensures reliability by detecting leaks with exceptional sensitivity while maintaining an optimized and programmable testing process.

This leak test system is a standardized solution for leak testing cooling systems assemblies at 10-5 using our MD-490S Dual Gas. It can also be used for other applications.

FEATURES

GENERAL

-

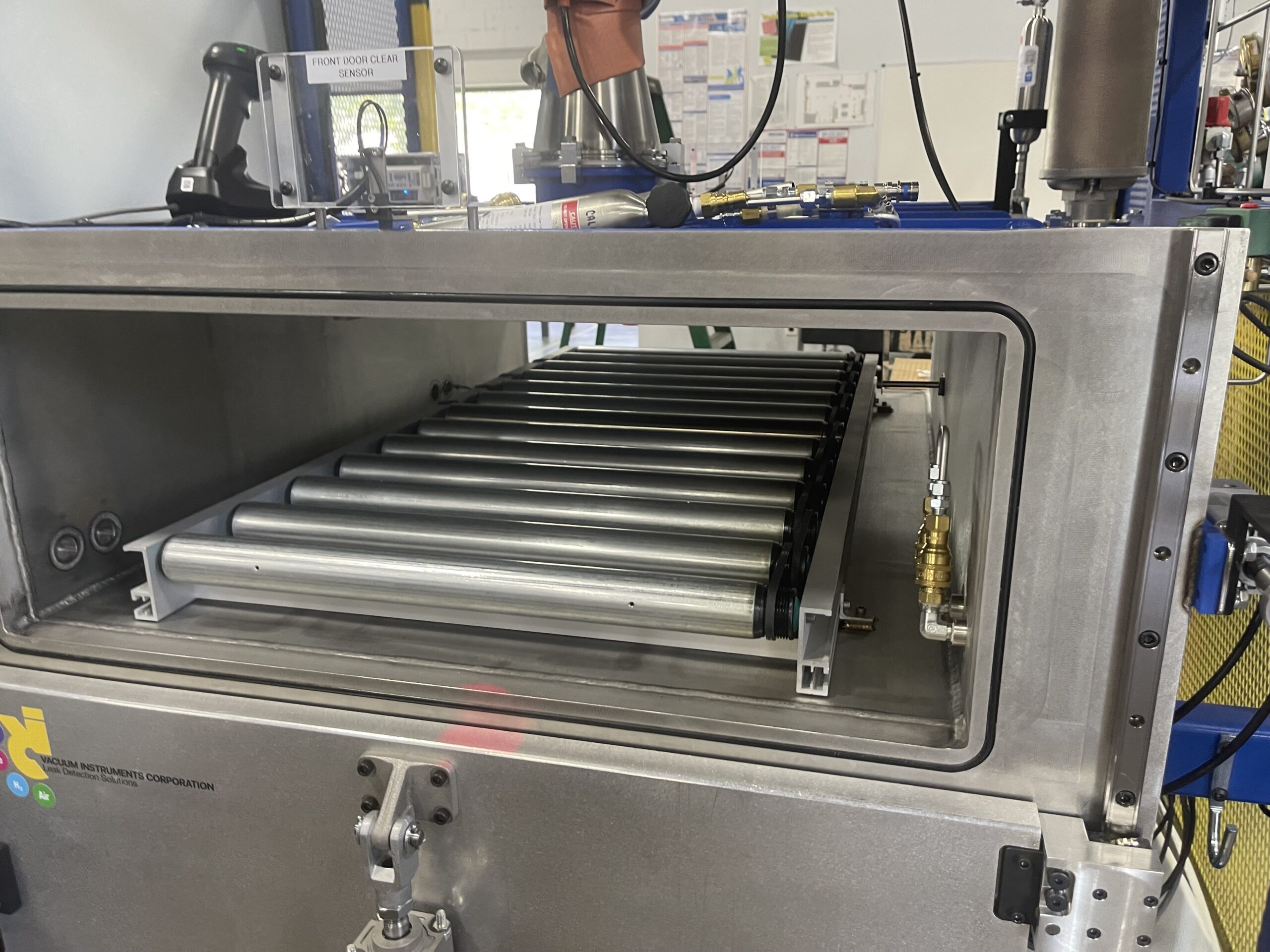

Fully Automated “Through” Chamber System – Equipped with automatic doors and a powered roller conveyor for seamless inline integration.

-

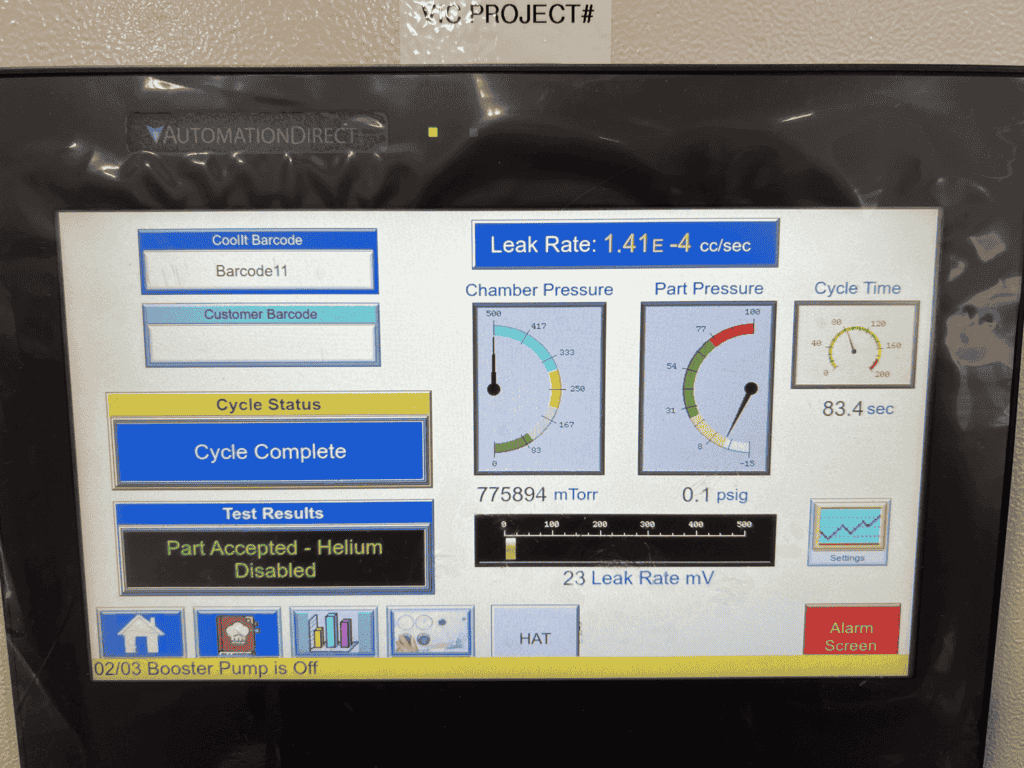

High-Precision Leak Detection – Capable of detecting leak rates in the mid 10⁻⁵ atm cc/sec.

-

Built-in Coolant Purge Function – Ensures contaminants are flushed out at the start of the cycle, automatically stopping if coolant is detected.

-

Programmable Cycling Capability – Allows multiple test cycles between high and low charge setpoints for enhanced reliability.

-

Customizable Charge Setpoints – Operates between 30-75 psig using a 10% Helium / 90% Nitrogen tracer gas.

-

Remote Pump Setup – Long-distance piping enables flexible pump placement in a separate room.

-

Optimized for Operator Safety & Comfort – Noise levels remain below 83 dBA at the operator station.

-

This system can be fully customized to meet your testing requirements.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.