UPGRADE YOUR LEAK DETECTOR

Upgrading existing equipment is a cost-effective way to bring new life to your leak detection system. Wide varieties of upgrades are available and can include hardware, software, or both.

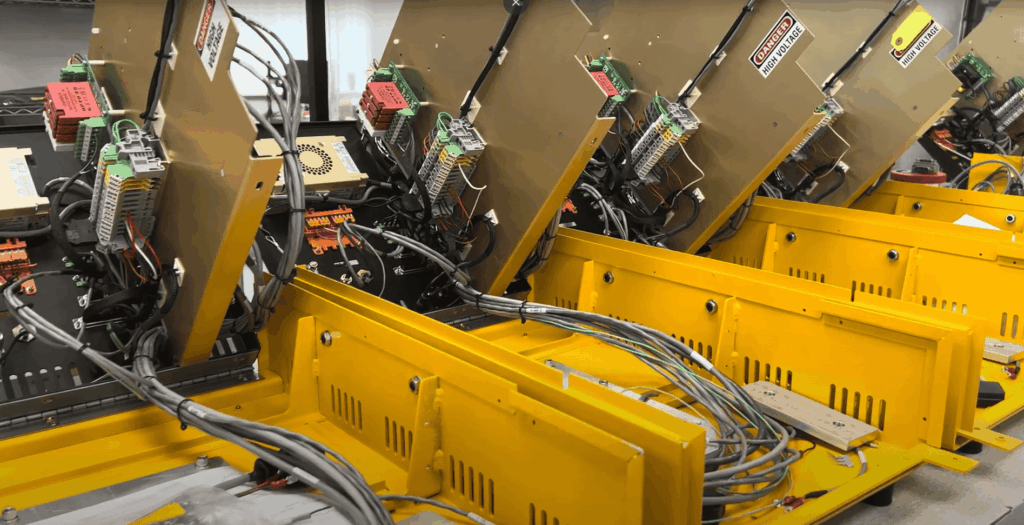

For example, existing equipment can be upgraded with new mechanical pumps; tooling can be upgraded with automation, electrical control panels can be replaced along with a new Human Machine Interface (HMI) and PLC software.

Software upgrades can also include data retention to record test data. Leak detectors can be upgraded whether they are from VIC or another supplier. Contact us today to discuss your custom or standard product upgrade options.

CHOOSE YOUR UPGRADE

Your existing VIC Leak Detection equipment can be upgraded with improvements that are implemented in our current product line:

- Improve cycle times

- Reduce downtime and maintenance costs

- Increase gas handling efficiency

- Calibrate in confidence (ISO 17025)

- Reduce helium background

HELIUM RECOVERY SYSTEM CONTROLS & ELECTRICAL

UPGRADE

ISOLATION FILTERING SYSTEM UPGRADE

TWO STEP CHARGE AND CHAMBER PURGE

UPGRADE

CHARGE CABINET

UPGRADE

EVERLASTING CALIBRATION GAS LEAK

UPGRADE

DYNAMIC HELIUM % PRESSURE COMPENSATION

UPGRADE

AUTO CALIBRATION/DIGITAL SIGNAL PROCESSING

UPGRADE

MS-50GT

UPGRADE

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.