ADVANCED LEAK TEST SOLUTIONS

VIC provides a comprehensive range of test equipment tailored to the automotive industry’s needs. Our innovative solutions ensure precise and reliable testing for a variety of applications, from component testing to complete system evaluations. With VIC’s advanced technology, automotive manufacturers can achieve unparalleled accuracy and efficiency in their testing processes.

Leak testing is a critical aspect of ensuring the integrity and performance of automotive components. VIC’s leak testing solutions are designed to detect even the smallest leaks, preventing potential failures and ensuring the longevity of automotive parts. Our equipment is capable of handling a wide range of materials and assemblies, making it an essential tool for automotive manufacturers.

Vacuum Instruments Corporation offers:

- Leak detectors for quality control at automotive manufacturing facilities worldwide

- Accurate and dependable leak testing for automotive production systems

- VIC expert technicians to assist with optimizing your leak testing process

- Custom systems to provide automation into your production environment

COMPREHENSIVE LEAK DETECTION FOR AUTOMOTIVE COMPONENTS

VIC has been at the forefront of automotive testing solutions for decades. Our expertise and commitment to innovation make us the preferred choice for automotive manufacturers worldwide. We continually invest in research and development to bring the latest advancements in test equipment and methodologies to our clients.

Fuel Tank

Fuel Injector

Exhaust Manifold

Powertrain System

EV Battery

Airbags

Cylinder Heads

Exhaust Systems

Gearbox

Oil Pan

Cooling Circuits

And more…

CUSTOM LEAK TEST SYSTEMS FOR AUTOMOTIVE APPLICATIONS

Every automotive manufacturer has unique testing requirements. VIC offers customizable test solutions that can be tailored to meet specific needs. Whether it’s leak testing, function testing, or any other application, our equipment is designed to provide flexible and scalable solutions that align with your production processes.

Fuel Rail Using the LeakID

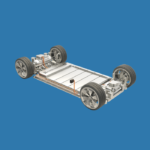

Drive Train

Thermal Evaporator

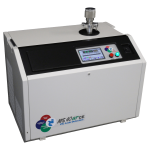

STANDARD TRACER GAS LEAK TESTERS

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.