HELIUM LEAK TEST SYSTEMS

LEAK TEST METHODS

SNIFFING METHOD

The sniffing method involves pressurizing the test piece with helium gas and using a handheld sniffer probe connected to a helium leak detector.

The probe is moved over potential leak points, and if helium escapes, the detector signals a leak. This method is ideal for locating precise leak sites in complex assemblies or systems under pressure. It’s particularly useful for pinpointing leaks in production environments and maintenance inspections.

BOMBING METHOD

The bombing method involves placing a test part in a high-pressure helium atmosphere, allowing helium to penetrate any leaks.

After a set period, the part is transferred to a vacuum chamber, and any helium escaping from inside is detected by a mass spectrometer. This method is effective for detecting internal leaks in sealed components like electronic devices and hermetically sealed containers.

COOLING SYSTEMS l DATA CENTER

Our advanced Through-Chamber Leak Testing System is designed for seamless integration into factory conveyor systems, providing efficient and automated testing of cooling system components used in large data centers. This high-precision system ensures reliability by detecting leaks with exceptional sensitivity while maintaining an optimized and programmable testing process. […]

AC HOSES l HVAC – SINGLE CHAMBER

This single chamber VIC Industrial Leak Test System is a high-performance, automated helium leak-testing solution designed for high-volume testing of AC hose assemblies. This self-contained system ensures precision leak detection while maintaining efficient throughput, making it ideal for industrial applications requiring reliable and accurate testing. […]

CONDENSERS l HVAC – DUAL INDEPENDENT CHAMBER

The VIC Industrial Leak Test System is a fully automated, high-volume helium leak-testing machine designed for precision and efficiency. This self-contained system is engineered to test up to 120 parts per hour across two chambers, ensuring rapid and accurate leak detection for industrial applications. […]

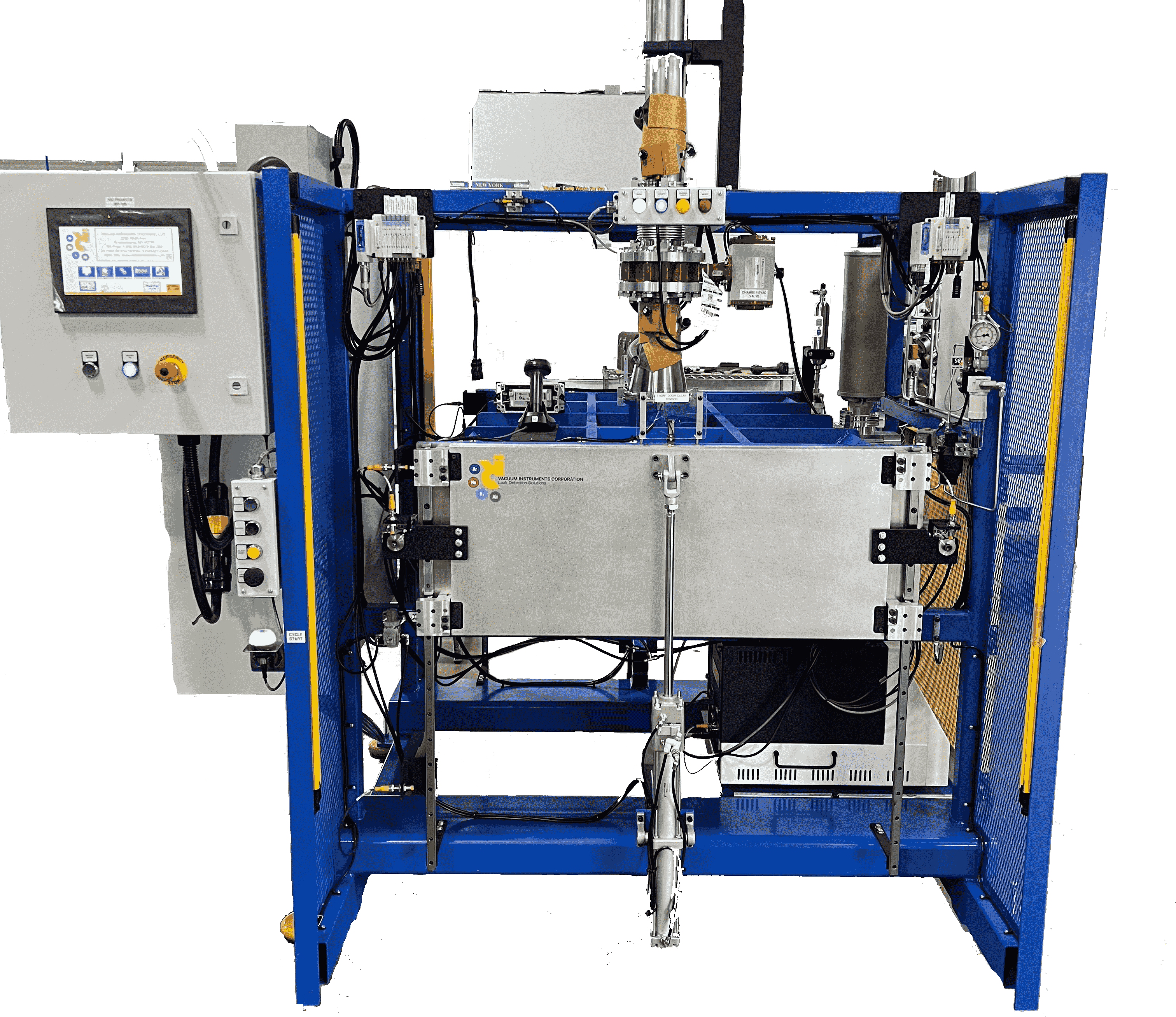

INTREPID l MILITARY & DEFENSE APPLICATION

The system uses helium molecular detection with a mass spectrometer leak detector and vacuum technology to determine the rate of helium leakage from a test part. The Intrepid is a standardized solution for leak testing nose cones and optics/guidance assemblies at 10-9 using our MS-50GT. It can also be used for other applications. […]

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.