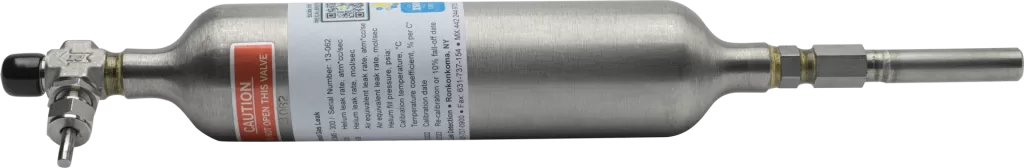

N.I.S.T CALIBRATED GAS LEAK

Every VIC designed is a N.I.S.T traceable calibrated gas leak onto each chamber. The gas leaks are required in order to properly calibrate and provide accurate quantified part leakage that is used to qualify the integrity of the customer’s product. Our gas leaks are filled to a specified pressure which allows both the desired leak rate and the discharge duration interval which is 12-months from the date of calibration. In order to maintain NIST certification and traceability while ensuring that the quality of the leak test is not compromised, each gas leak must be returned to VIC for the following calibration service:

- Measurement of the gas leak as-received and determine if the leak is out of tolerance.

- Inspection of the capillary leak element (excludes SC leaks)

- Evacuation of the cylinder (excludes SC leaks)

- Recharge the leak cylinder with the desired tracer gas to the required fill pressure (excludes SC leaks)

- Calibration and comparative measurements using 2x additional NIST traceable gas leaks

- Certificate of calibration for each leak

- Data storage including historical calibration information for all of our gas leaks

GAS LEAK RECALIBRATION SERVICES

In order to maintain NIST traceability each gas leak requires recalibration 12-months from the last date of calibration. Our gas leaks are available for recalibration at our Corporate office in NY or our office in QRO Mexico and Include a certificate of calibration traceable to NIST.

Recalibration Services include a certificate with traceability to N.I.S.T. on all of our manufactured leaks and all non-VIC manufactured leak standards as well. Exchanges are available on all SC7 gas leaks with lead times of 24-48 hours. For more information contact VIC.

EXCHANGE PROGRAMS

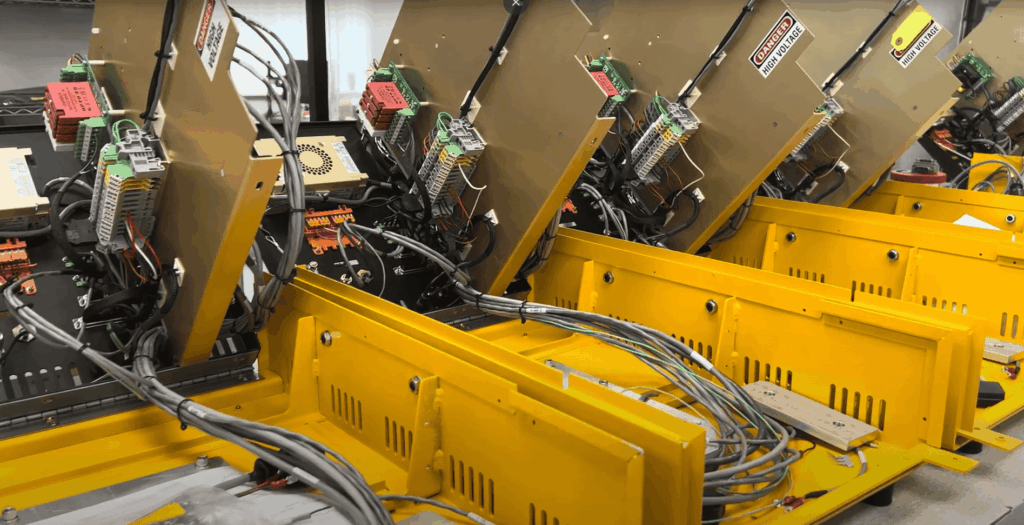

The Exchange Program provides customers with factory refurbished, repaired, or recalibrated assemblies that are ready for immediate installation. Most exchange items are available within 24-48 hours, allowing customers to reduce downtime as well as their inventory of on-hand spare parts.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.