HELIUM LEAK DETECTOR

Multiple Solutions For Leak Detection Application Requirements

VIC designs and manufactures portable portable helium tracer gas leak detectors, console tracer gas leak detectors, helium and dual gas portable leak detectors with sniffing and fully integrated smart charge and back-fill station, integrated tracer gas leak detection systems, calibrated gas leaks, and accessories.

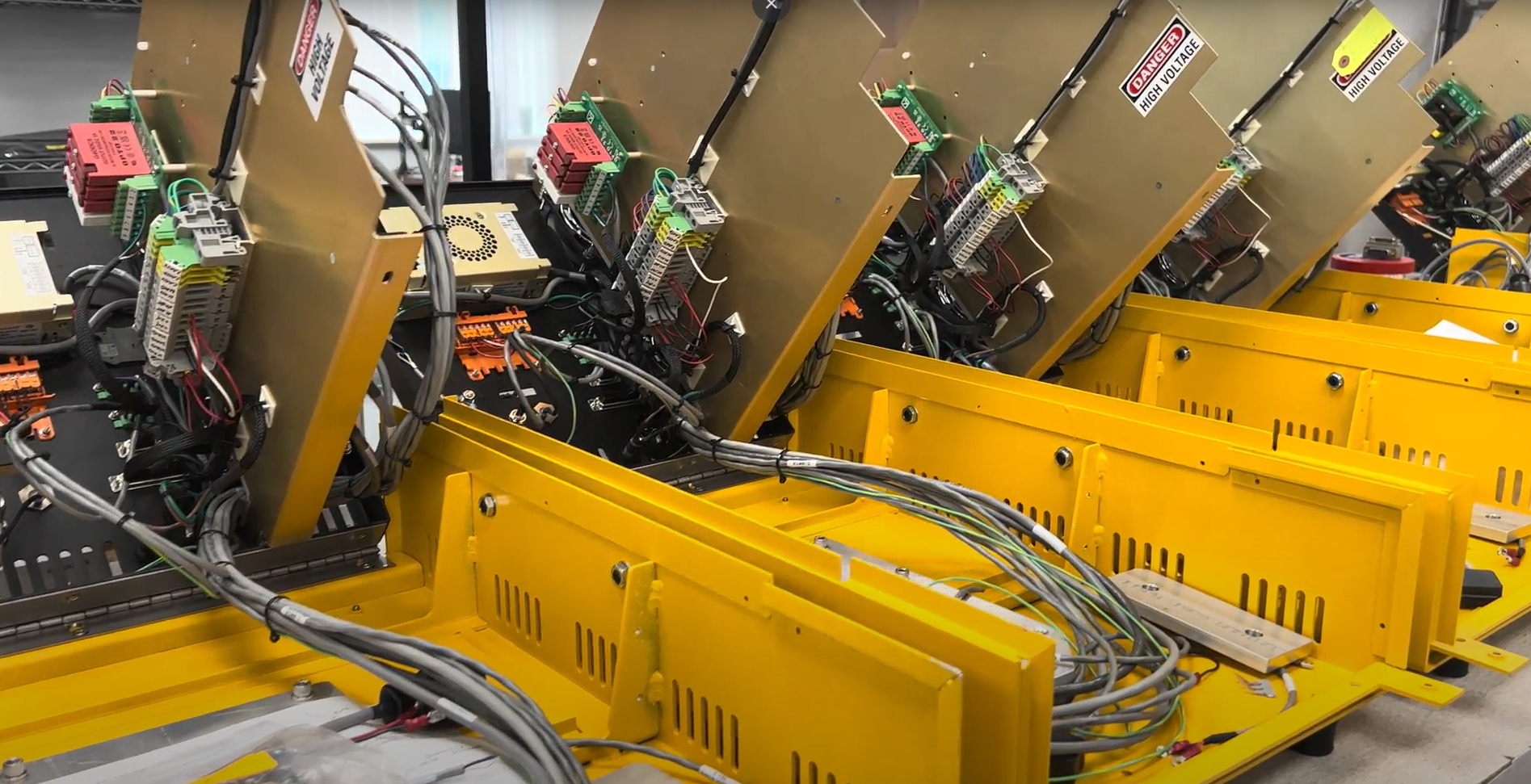

Custom Integrated Leak Detection Systems Engineering

Our base system technologies can be custom engineered to include integrated tooling/fixtures, automation and control, application-specific features, leak standard data collection requirements, and more. Please call us for custom engineering our systems, we have a customer-centric and application specific approach and integrated design project engineering to build systems that meet customers needs.

HYDROGEN LEAK DETECTOR

Portable Hydrogen Sniffing Leak Detector.

MD-490S Dual Gas is the most advanced sniffing Helium/Hydrogen leak detector designed specifically for industrial environments. The MD-490S Dual Gas utilizes VIC’s own industrial-grade mass spectrometer to achieve the highest sensitivity, fastest response-time, and smallest footprint. With a touch of a button, this dual gas unit can detect either Helium or Hydrogen tracer gases, while using a single built-in dual purpose calibrated gas leak.

ARGON LEAK DETECTOR

For highest sensitivity and greatest accuracy

The heart of the most sensitive and accurate instrument for detecting extremely small leaks is the mass spectrometer, which is used to measure the rate of flow of a tracer gas through leaks using vacuum, pressure or vacuum-pressure techniques. The mass spectrometer detects the tracer gas and converts it to an electrical signal proportional to the size of the leak. Argon is usually used as a tracer gas because of its unique combination of properties:

- Argon is extremely rare in the atmosphere, so there is little ambient “noise” to interfere with leak measurement

- Non-explosive, non-toxic, completely inert (no contamination of the tested product)

- It will not contaminate and desensitize its own detector as is common with detectors using other tracers.

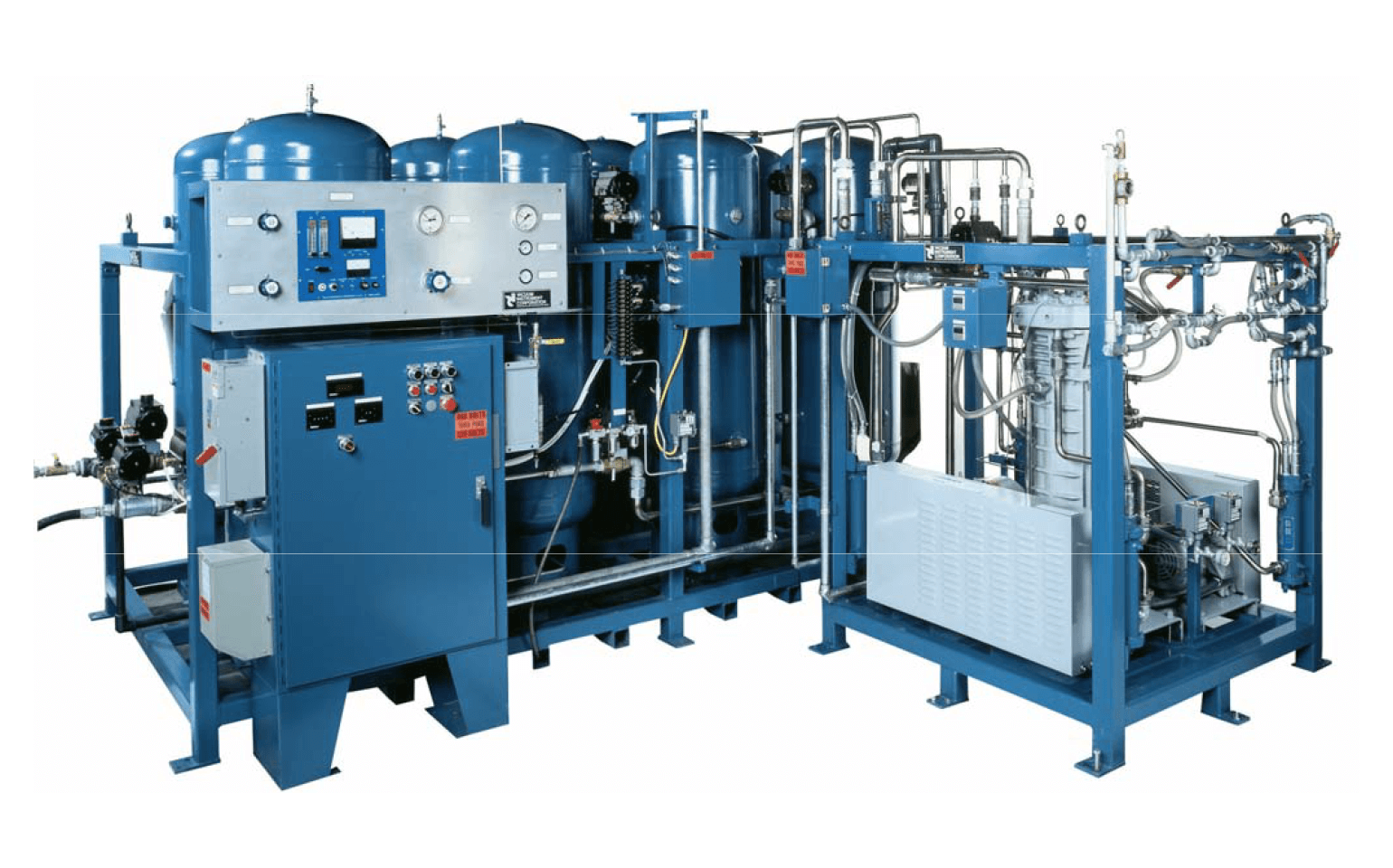

GAS HANDLING SYSTEMS

GAS HANDLING SYSTEMS

Gas Charge/Mixer/Blender and Booster/Amplifier Systems

Vacuum Instruments Corporation designs and manufactures industrial helium hard vacuum systems, accumulation sniffer systems, gas mixing, gas boosting, gas charging, gas recovery systems, and bombing stations, as well as variety of calibrated gas leaks including helium, hydrogen, and argon.

These systems are designed to facilitate the mixing or blending of different gases to achieve specific concentrations or properties, which are essential in processes like manufacturing, calibration, and testing. The gas booster/amplifier systems, on the other hand, are vital for applications requiring gas at higher pressures than what is available from the source. They amplify or boost the pressure of the gas to meet the specific requirements of various industrial processes, ensuring efficiency and reliability in operations where gas pressure is a critical factor. Both types of systems are built with a focus on precision, durability, and safety, reflecting Vacuum Instruments Corporation’s commitment to providing high-quality solutions for complex industrial challenges involving gas handling and processing.

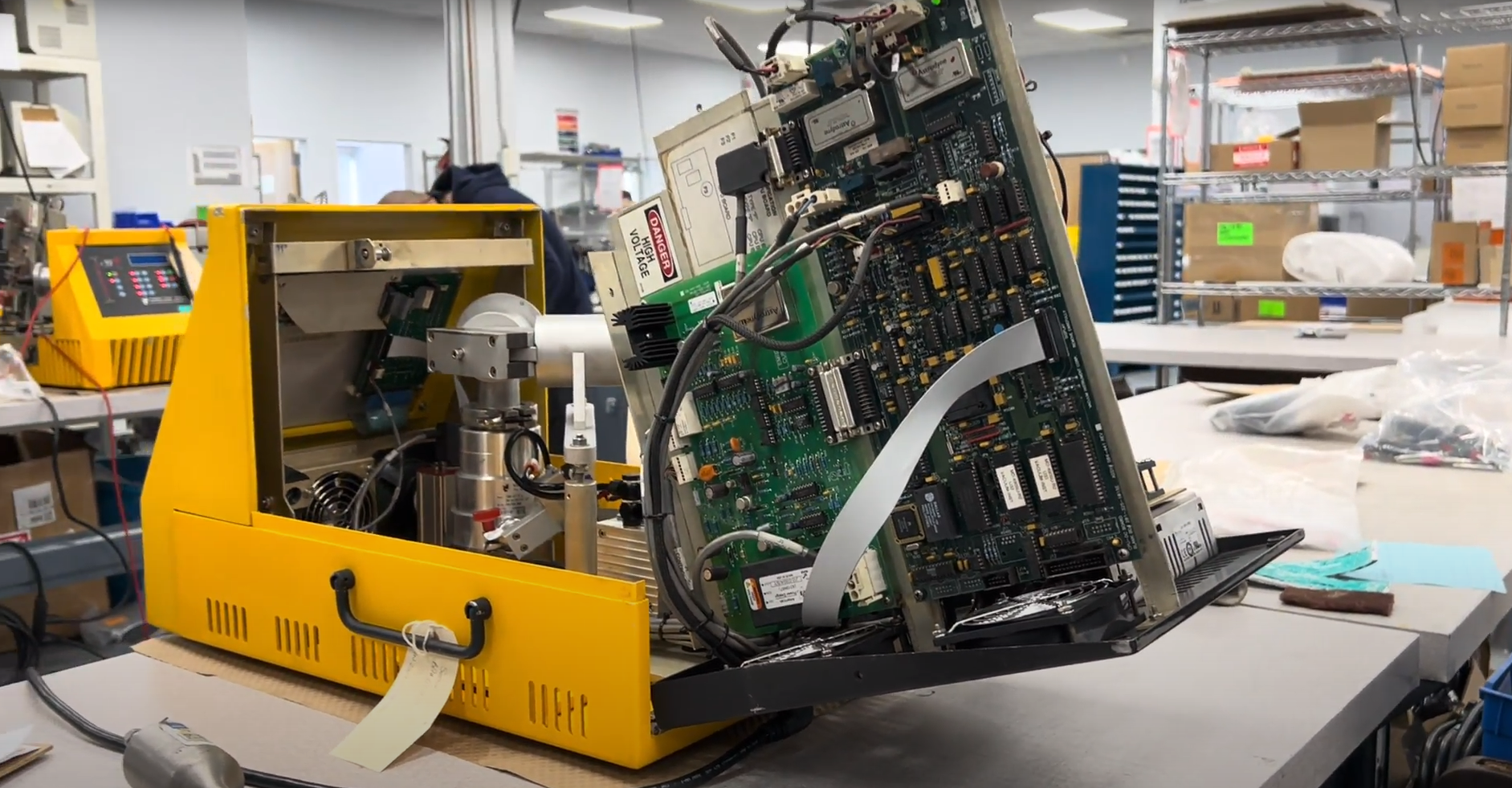

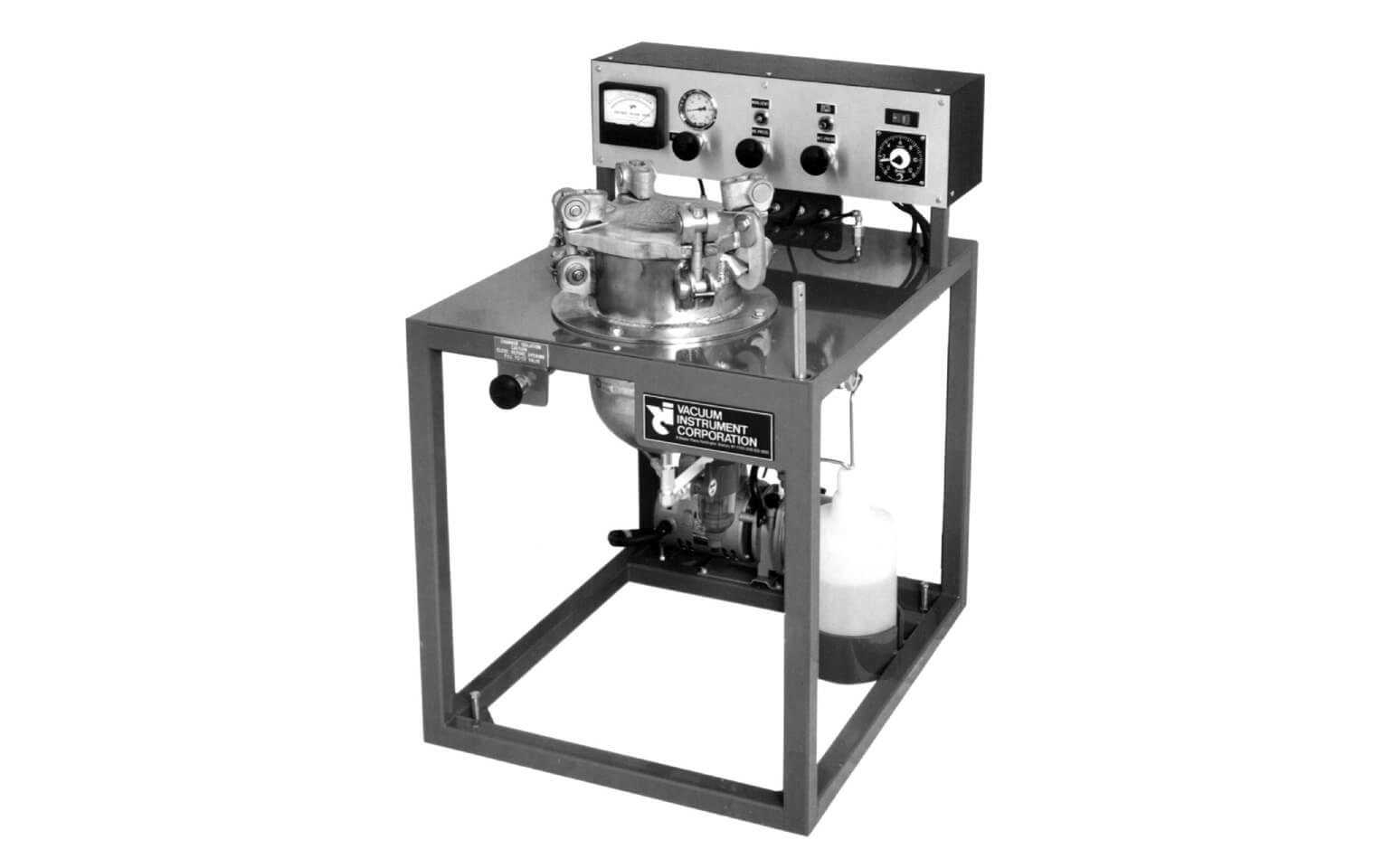

BOMBING STATIONS

BOMBING STATIONS

Custom bombing stations for your testing needs

VIC Helium Bombing Stations are designed for bombing hermetically sealed devices in conformance with MIL-STD 883E, 750 and 202. Helium Bombing Stations are offered with a variety of chamber configurations. Your units may be configured from our large stock of standard components, or designed and built from the ground up to meet your special requirements.

Bombing stations are used in helium leak detection to pressurize test objects with helium or another tracer gas, a process known as “bombing.” This prepares the object for leak testing by ensuring that any leaks present will emit the tracer gas, which can then be detected by specialized equipment. These stations provide precise control over the pressurization, ensuring the object is safely exposed to the right amount of gas, enhancing leak detection without damaging the item. This method is essential in industries where detecting even the smallest leaks is critical, such as in medical device, automotive, and electronics manufacturing.

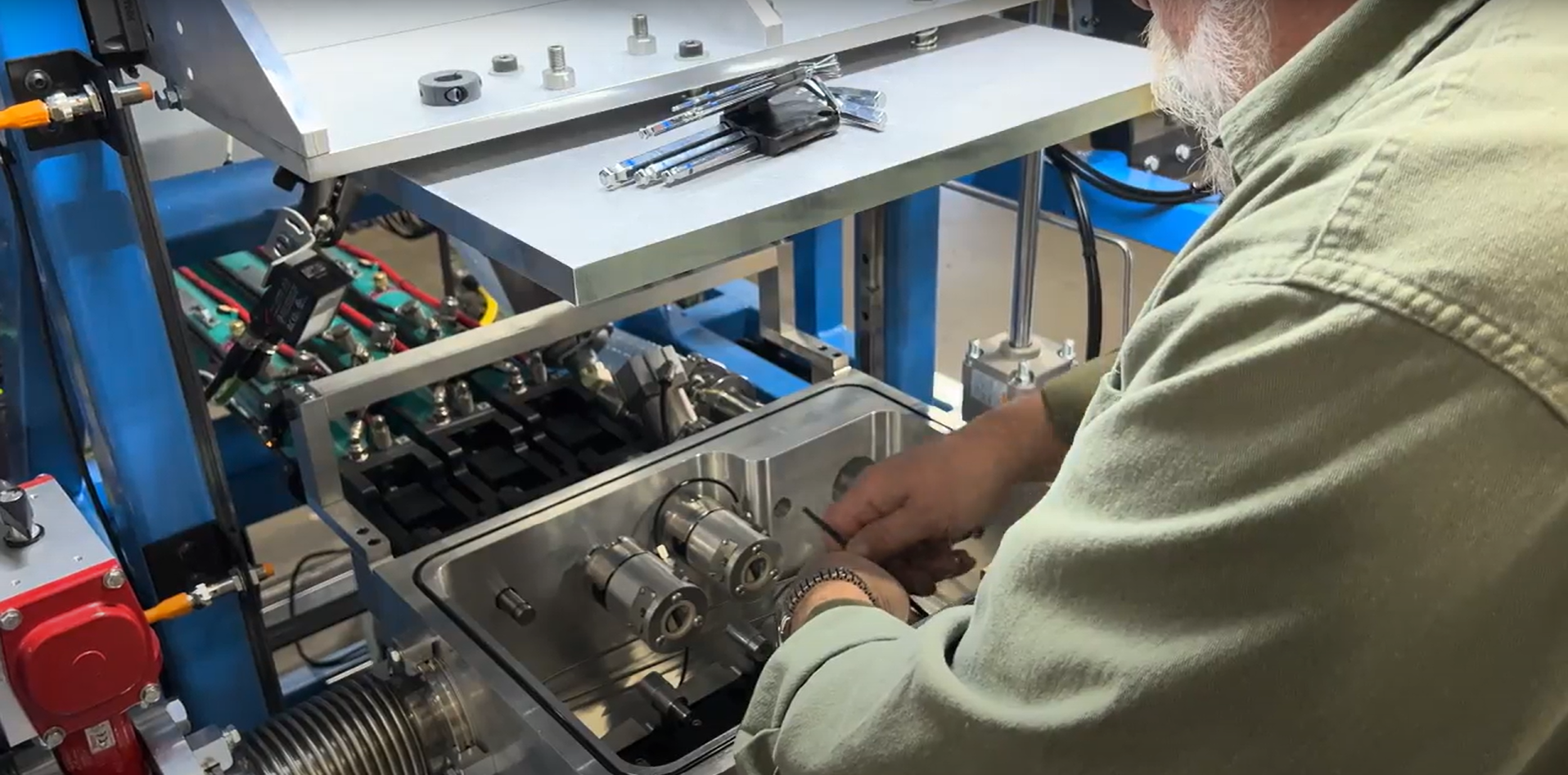

BACKFILL STATIONS

BACKFILL STATIONS

Custom Backfill station for your testing needs

Vacuum Instruments Corporation designs and manufactures industrial helium hard vacuum systems, accumulation sniffer systems, gas mixing, gas boosting, gas charging, gas recovery systems, and bombing stations, as well as variety of calibrated gas leaks including helium, hydrogen, and argon.

A backfill station serves a crucial role in preparing the test object for or restoring it after a leak detection process. During helium leak testing, especially in hard vacuum or sniffer modes, the object being tested is often evacuated to create a suitable environment for introducing helium as a tracer gas. After the leak testing is completed, it's important to return the tested object to its normal state, which often means refilling or "backfilling" it with a specific gas, such as air or nitrogen, to a predetermined pressure level.

The backfill station ensures that this process is conducted efficiently, safely, and in a controlled manner. By using a backfill station, operators can accurately control the flow and pressure of the gas used to refill the test object, ensuring that it is ready for its next use without compromising its integrity or the accuracy of subsequent tests. This step is especially important in industries where the purity and pressure of the internal atmosphere are critical to the operation or integrity of the component, such as in aerospace, automotive, and semiconductor manufacturing.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.