CASE STUDY: REDUCING HELIUM WASTE WITH SMARTER GAS-LEAK TESTING

CASE STUDY: REDUCING HELIUM WASTE WITH SMARTER GAS-LEAK TESTING

Many factories experience irregular results for leak tests, resulting in more waste or returned products. Coordinating preparation and detection, as well as optimizing tracer gas use, can ensure that quality is maintained at an effective cost. The following case study illustrates how VIC’s Smart Charge 5, combined with a recovery system, helps manufacturers get more consistent output.

The Challenge

AI servers generate significant heat, pushing cooling manufacturers to build ever more efficient systems.

In leak testing, doing things differently each time causes problems: good parts are rejected while faulty ones make it through. On the other hand, using too much tracer gas, especially helium, adds unnecessary costs and may cause supply issues.

The Approach

AI servers generate significant heat, pushing cooling manufacturers to build ever more efficient systems.

One streamlined leak‑testing flow:

- Prepare each part the same way. Use Smart Charge 5 to remove air and check for big leaks first. Then, add tracer gas using pre-set instructions.

- Find leaks fast. Use a mass spectrometer such as the MD-490s Dual Gas to pinpoint leak locations.

- Reuse the gas. Capture and reuse tracer gas using a recovery system to reduce waste.

This shifts testing from relying on who’s doing it to being a consistent process. This means results are the same every time.

What You Can Expect

- Lower scrap and rework: Catching big leaks early on and accurately finding small ones keeps good parts from being rejected.

- Better first-time success: Preparing consistently cuts down on false alarms and makes measurements more reliable.

- Gas costs under control: Recycling loops reduce the amount of new tracer gas needed.

- Faster troubleshooting: Knowing exactly where the leak is speeds up problem-solving.

Why Smart Charge 5?

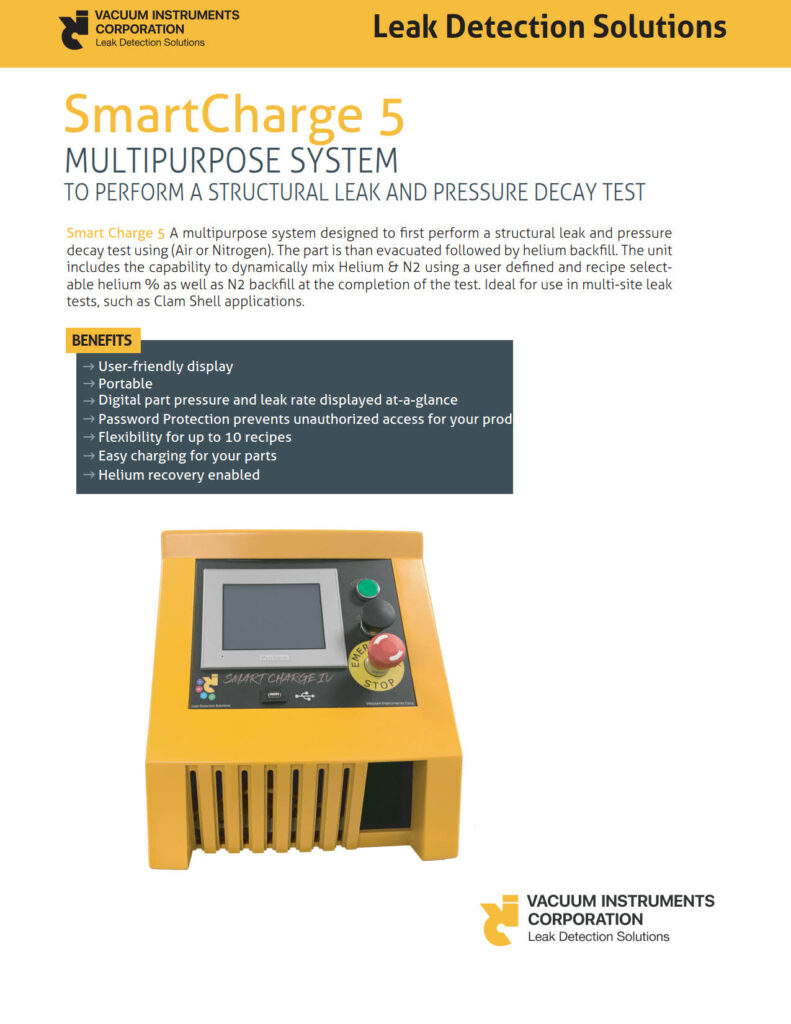

Smart Charge 5 makes leak-testing preparation more consistent by using pre-set instructions for removing air and refilling with tracer gas. It also records each cycle to keep operators on the same page and ensure stable measurements.

The VIC Smart Charge device is designed to fit into all kinds of production settings, such as automotive, HVAC, medical, or aerospace. It can use different tracer gases, such as helium for the best sensitivity, or forming gas (5% hydrogen / 95% nitrogen) with the proper safety measures.

Good to Know

*As volumes grow, pairing Smart Charge 5 with a helium‑recovery loop helps control costs by capturing the gas and reusing it for testing.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.