Bombing stations, specifically helium bombing stations, are essential in industries requiring precise leak detection, such as automotive, aerospace, and electronics. These stations introduce helium, a tracer gas, into the test parts under controlled pressure to identify even the smallest leaks. By pressurizing components with helium, bombing stations ensure accurate and reliable leak detection, crucial for maintaining high-quality standards and safety.

Custom Solutions for Hermetically Sealed Components

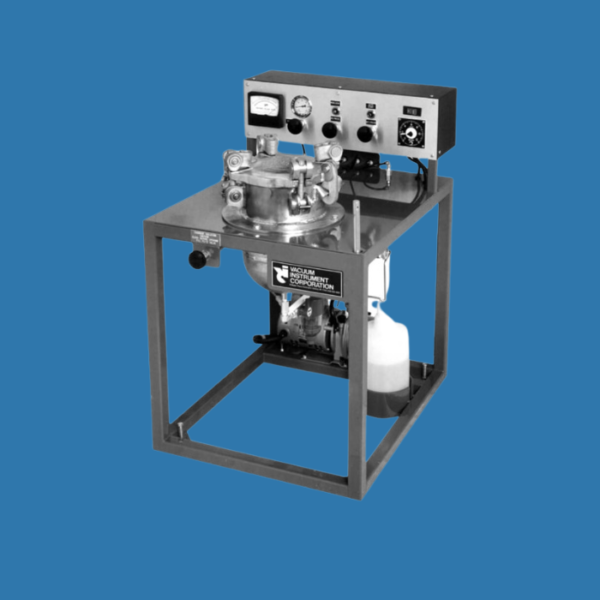

VIC Helium Bombing Stations are designed for bombing hermetically sealed devices in conformance with MIL-STD 883E, 750 and 202. Helium Bombing Stations are offered with a variety of chamber configurations.

Specialty and custom units may be configured from our large stock of standard components, or designed and built from the ground up to meet your special requirements.

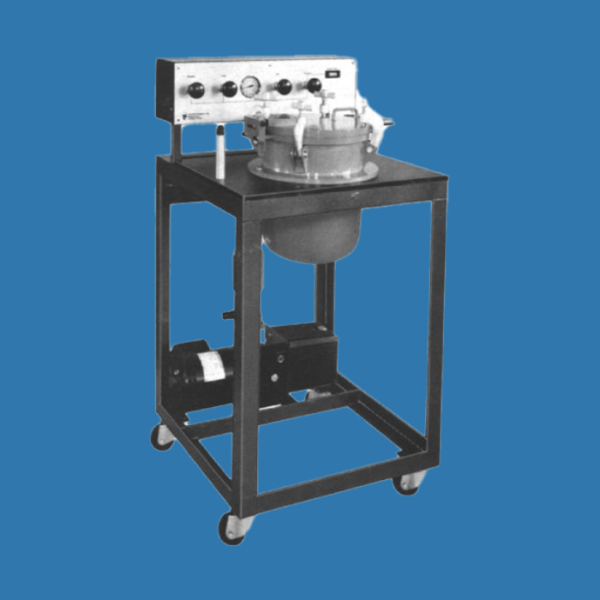

Helium bombing stations, like the VIC PBS-1 and PBS-2, streamline the leak detection process. The PBS-1 offers a single-chamber design, ideal for efficient and reliable testing, while the PBS-2 features a dual-chamber setup, allowing simultaneous testing to reduce overall test times. These stations are designed to integrate seamlessly into existing testing protocols, making them a cost-effective solution for high-precision leak detection.

In addition to helium, some bombing stations, such as the VIC PV883 and PV883 Junior, support dual-purpose testing with both helium and fluorocarbon tracer gases. These versatile stations cater to various testing needs, providing consistent and accurate results for different applications. Whether for high-volume or low-volume operations, helium bombing stations are indispensable tools in ensuring the integrity and safety of critical components across industries.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.

Vacuum Instruments Corporation is a pioneer in providing state-of-the-art leak detection solutions for diverse applications and industries. Our systems have ensured the safety and performance of countless products that we use in our daily lives from the cars we drive to the air conditioners in our houses, the pacemakers in our bodies, and the satellites we launch into space.